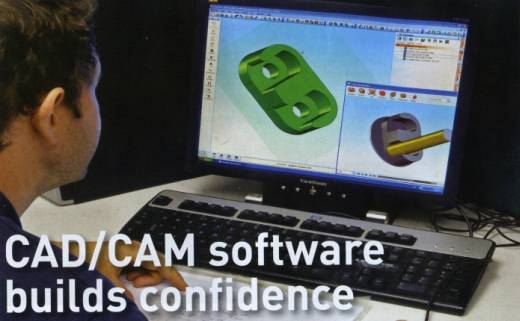

OneCNC CAD/CAM software builds confidence

Nick Groom (below) uses the OneCNC CADCAM system to help program a complex component for mill-turning on one of the company’s Star sliding-head lathes.

From a low point at the start of 2009, business at precision turned parts subcontractor, Qualiturn, has increased month on month throughout the year. But, said managing director, Nick Groom, a typical batch size ordered by customers is currently 1,000-off, which is about 50 per cent lower than last year.

It is more expensive to produce smaller quantities, as set-up time becomes a larger proportion of total manufacturing time. It should mean that the unit cost to the customer is higher, but in a recession, it is difficult to pass on the cost increase.

In these circumstances, to allow it to make reasonable margins, Qualiturn has managed to minimise set-up times through ongoing investment in engineering software and computer-controlled storage systems for raw material and tools. With 70 set-ups per week, the importance of streamlining procedures is evident.

The latest investment, in June 2009, was the purchase of CADCAM software from OneCNC. The Windows-based module has integrated functionality from CAD design though to machine posting. The package allows electronic 3D data supplied by customers to be translated and converted rapidly into NC code for running on the company’s 16 Star sliding-head CNC lathes and two Miyano fixed-head mill-turn centres.

Commented Mr Groom, “Customers are asking us to produce increasingly complicated components to ever higher accuracies. Until recently, we had to program 3D profiles manually, which often delayed the start of production.

“The OneCNC software generates complex tool paths directly from the original CAD data, which is quick and eliminates the risk of human error.

“We still write the remainder of the program at the machine control, as it is faster for simple routines. The two parts are then merged to create the final code much more quickly than previously.

“It is also possible to simulate a cutting cycle on-screen to make sure a program will run as expected.”

Lead-time from receipt of order to first article inspection of complex components is therefore faster than before, helping to reduce set-up time. Assisting further in speeding changeover is rapid delivery of material and tools to the machines, helped by Qualiturn’s investment in a 7.5 m-high tower for storing bar stock and a smaller version for housing tooling and machine attachments.

The latter was installed at the end of 2008, making it faster to access collets, bushes, toolholders and other items than when they were held in chests of drawers on the shop floor. Some boxes of special cutting tools are also housed in the multi-level store along with toolholders for regularly repeating jobs, but most cutters and tips are stored in an Autocrib.

The subcontractor operates the multi-level tool store differently from the bar store. The latter is linked directly into a PSL Datatrack production management system, which automatically calls up the bar and delivers it to an unloading area at floor level as a job starts its progression through the Hertford factory. Within the tool store, the content of each shelf is similarly held within the Datatrack memory, but the operator manually keys in the appropriate shelf number at a control panel to access the tooling.

Speeding machine set-up not only makes smaller batches more economical but also reduced spindle downtime, helping to extract maximum productivity from all of the subcontractor’s plant. Attendant technologies from job sales order processing and workshop scheduling through to CNC inspection and billing, all linked into and overseen by Datatrack, similarly contribute to maximising throughput.

So too does the speed of the latest CNC lathes, which have higher feed rates and spindle speeds and enhanced capabilities compared with machines that are just a decade old. So Qualiturn adopts a policy of renewing its machines after eight years at the latest. The most recently installed Stars, for example, have up to 35 m/min rapids and are capable of cutting cycles that are twice as fast as older machines. Along with quicker set-ups, the inherent speed of modern machines also helps to lower unit production costs.

A further contribution to this goal is Qualiturn’s consultancy service, whereby a new component design can be reappraised and suggestions made as to how it could be modified to reduce the cost of machining. The service is provided at no extra charge, on the basis that the subcontractor’s service will give it a commercial advantage.

Real cost savings are possible. Mr Groom points to a recent aerospace job where Qualiturn engineers looked at different shaft diameter and material combinations to optimise production of a non-critical component. In another example, a 15 per cent cost reduction was achieved when machining an automotive component by mill-turning it in one hit from 20 mm diameter brass bar rather than using expensive extrusion.

Although 1,000-off is a typical batch size for Qualiturn and turnaround time is currently one to two weeks, Mr Groom stressed that his company regularly produces 10,000- and 20,000-off, but less frequently since the start of the year.

He concluded, “At the moment, a lot of our customers do not want to order large quantities and tie up money by holding inventory. So they are tending to opt for smaller batches and order them more frequently for just-in-time delivery, even though it costs a bit more.

“On our side, we cannot risk producing more than the customer orders and stocking the surplus on consignment, as designs can change and products can be discontinued.

“So our efforts to reduce set-up times have been crucial in the current economic climate. They have allowed Qualiturn to mitigate the extra cost of producing smaller batches and enabled us to adapt to market conditions by offering lower prices and faster delivery.”

Qualiturn Products Ltd

18 Merchant Drive

Mead Lane Industrial Estate

Hertford, Herts, SG13 7AY

Tel: 01992 584499

Fax: 01992 551726.

E-mail:

Web site: www.qualiturn.co.uk

Contact: Nick Groom, Managing Director

OneCNC Updates

OneCNC XR9 Release 74.80

Apr 01 2024

OneCNC XR9 Release 74.77

Feb 28 2024

OneCNC XR9 Release 74.68

Feb 13 2024